- EV-TronixHome

- AC/DC Contactors

- AC/DC Contactors

AC/DC Contactors

EV-Tronix carries LS Electric High Voltage DC Relays which serve to supply and disconnect the DC power, and contains hydrogen and nitrogen gas, which is optimized to withstand production and breaking. As a result, it has excellent electrical durability, is compact in size, and produces low noise.

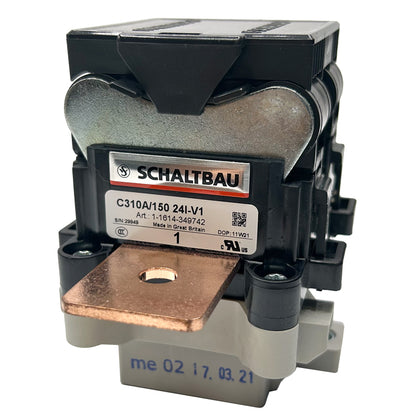

AC Contactors are utilized in a variety of applications where the control of high-power electrical loads is required. Key applications include motor control, lighting systems, HVAC systems, and more. DC Contactors are specifically designed for switching direct current (DC) circuits up to 1000V. Thanks to the efficient breaking of DC circuits, the product range is one of the most compact on the market for applications such as PV Solar, UPS, and Energy storage systems.

- Compact Design - Achieved a compact size by filling with hydrogen and nitrogen gas to improve breaking performance

- Proven Safety - Withstands a high value of short circuit current

- Superior Reliability - Excellent performance with electrical and mechanical endurance IEC, UL, CCC certified

- Compact Design - Achieved a compact size by filling with hydrogen and nitrogen gas to improve breaking performance

- Proven Safety - Withstands a high value of short circuit current

- Superior Reliability - Excellent performance with electrical and mechanical endurance IEC, UL, CCC certified

- Compact Design - Achieved a compact size by filling with hydrogen and nitrogen gas to improve breaking performance

- Proven Safety - Withstands a high value of short circuit current

- Superior Reliability - Excellent performance with electrical and mechanical endurance IEC, UL, CCC certified

- Compact Design - Achieved a compact size by filling with hydrogen and nitrogen gas to improve breaking performance

- Proven Safety - Withstands a high value of short circuit current

- Superior Reliability - Excellent performance with electrical and mechanical endurance IEC, UL, CCC certified

- Compact Design - Achieved a compact size by filling with hydrogen and nitrogen gas to improve breaking performance

- Proven Safety - Withstands a high value of short circuit current

- Superior Reliability - Excellent performance with electrical and mechanical endurance IEC, UL, CCC certified

- Low consumption power

- High density power

- Saving panel size

- Installation space is reduced by 50% of conventional DC operated contactors achieving high performance

- Low consumption power

- High density power

- Saving panel size

- Installation space is reduced by 50% of conventional DC operated contactors achieving high performance

- Reliable in the system: Type ∥ coordination

- Perfect system with peripheral devices

- No arc exposure via sealed structures

- One-touch connection with Din Rail

- Simple wiring with adapter, reversing wire set

- 4-terminal type: Easy wiring of operation coil

- Module type screw terminal

- Interlocking unit with built-in auxiliary contacts (2NO built-in)

- Reliable in the system: Type ∥ coordination

- Perfect system with peripheral devices

- No arc exposure via sealed structures

- One-touch connection with Din Rail

- Simple wiring with adapter, reversing wire set

- 4-terminal type: Easy wiring of operation coil

- Module type screw terminal

- Interlocking unit with built-in auxiliary contacts (2NO built-in)

- Reliable in the system: Type ∥ coordination

- Perfect system with peripheral devices

- No arc exposure via sealed structures

- One-touch connection with Din Rail

- Simple wiring with adapter, reversing wire set

- 4-terminal type: Easy wiring of operation coil

- Module type screw terminal

- Interlocking unit with built-in auxiliary contacts (2NO built-in)

- Reliable in the system: Type ∥ coordination

- Perfect system with peripheral devices

- No arc exposure via sealed structures

- One-touch connection with Din Rail

- Simple wiring with adapter, reversing wire set

- 4-terminal type: Easy wiring of operation coil

- Module type screw terminal

- Interlocking unit with built-in auxiliary contacts (2NO built-in)

- Reliable in the system: Type ∥ coordination

- Perfect system with peripheral devices

- No arc exposure via sealed structures

- One-touch connection with Din Rail

- Simple wiring with adapter, reversing wire set

- 4-terminal type: Easy wiring of operation coil

- Module type screw terminal

- Interlocking unit with built-in auxiliary contacts (2NO built-in)

- Reliable in the system: Type ∥ coordination

- Perfect system with peripheral devices

- No arc exposure via sealed structures

- One-touch connection with Din Rail

- Simple wiring with adapter, reversing wire set

- 4-terminal type: Easy wiring of operation coil

- Module type screw terminal

- Interlocking unit with built-in auxiliary contacts (2NO built-in)

- Reliable in the system: Type ∥ coordination

- Perfect system with peripheral devices

- No arc exposure via sealed structures

- One-touch connection with Din Rail

- Simple wiring with adapter, reversing wire set

- 4-terminal type: Easy wiring of operation coil

- Module type screw terminal

- Interlocking unit with built-in auxiliary contacts (2NO built-in)

- Overload relay for motor protection

- Screw terminals

- Auxiliary contacts 1 x NO/NC

- Manual/Automatic reset

- Rated insulation voltage Ui up to 1,500 V, version with small arc chamber

- Rated short-circuit making capacity Icm up to 2,500 A

- Conventional free air thermal current Ith up to 500 A

- Rated short-time withstand current Icw up to 3,000 A

- Rated insulation voltage Ui up to 1,500 V, version with small arc chamber

- Rated short-circuit making capacity Icm up to 2,500 A

- Conventional free air thermal current Ith up to 500 A

- Rated short-time withstand current Icw up to 3,000 A

- Rated insulation voltage Ui up to 1,500 V, version with small arc chamber

- Rated short-circuit making capacity Icm up to 2,500 A

- Conventional free air thermal current Ith up to 500 A

- Rated short-time withstand current Icw up to 3,000 A

- Hermetic seal with gas fill

- Optional auxiliary contacts – for main position feedback

- Meets RoHS 2011/65/EU

- CE certified

- Hermetic seal with gas fill

- Optional auxiliary contacts – for main position feedback

- Integrated coil economizer to reduce coil holding power

- Meets RoHS 2011/65/EU

- CE certified

- 1200A Continuous Duty

- 1500V System Voltage

- Hermetic Ceramic Seal with gas fill for superior carry and switching performance

- Bi-Directional main contacts

- Mechanically linked SPDT auxiliary contacts for accurate main position feedback

- Meets RoHS 2011/65/EU

- RoHS / REACH compliant

- UL 60947-4 pending